Quality

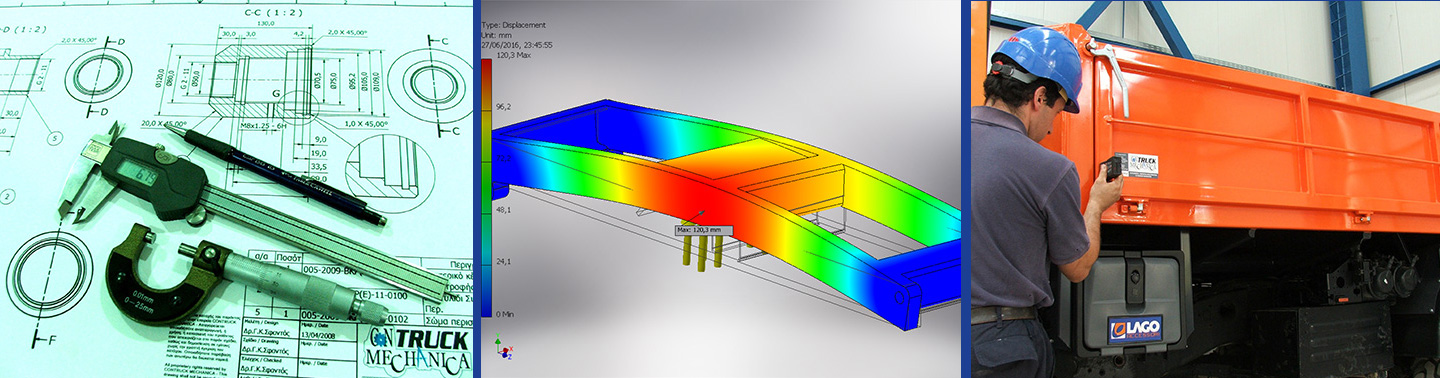

Quality and reliability are the main objectives of our product development. For this reason we systematically check our production process at every stage of design, construction and operation.

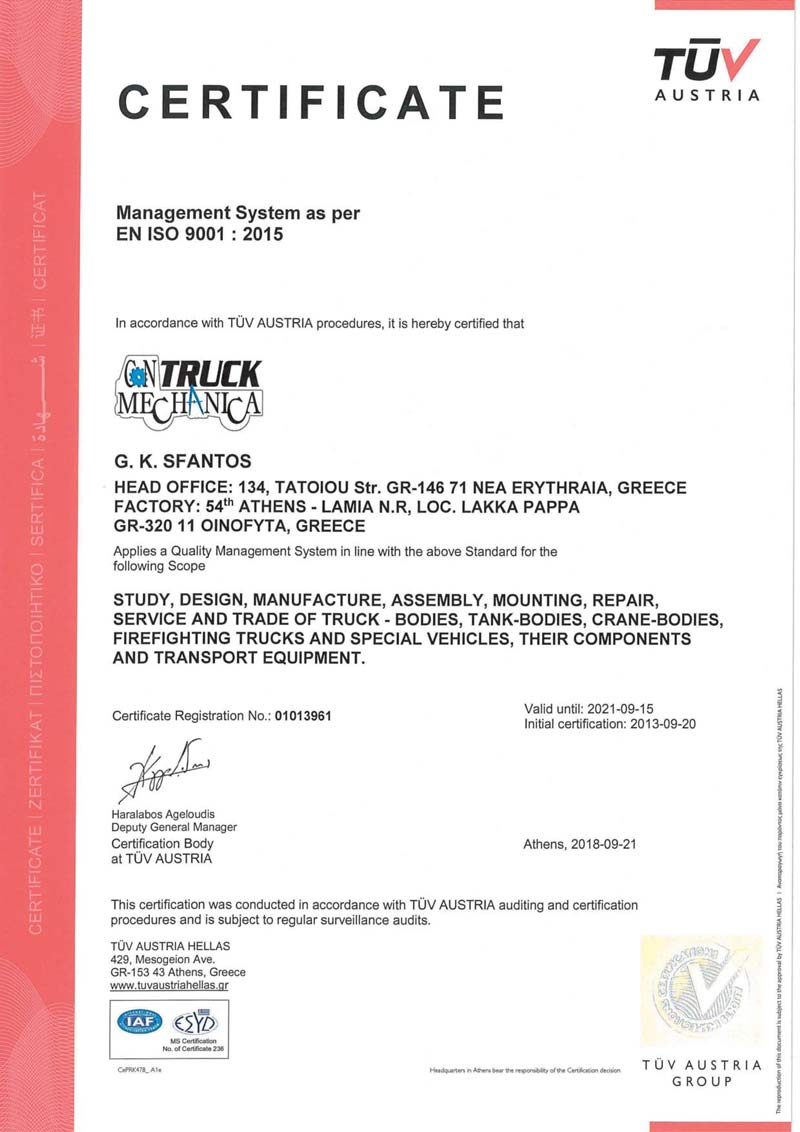

By using brand new raw materials, inspected machinery and quality certified engineering components; we have managed to ensure customers’ satisfaction and exceptional quality of our truck-bodies, certified in accordance with EN ISO 9001 by TÜV AUSTRIA HELLAS.

PAINTING

During the truck-body manufacturing, apart from the technical specifications, special attention is also given to the anti-rusting protection and painting. The truck-body development takes place on a special-made base and not on the chassis of the truck. In this way the optimum quality of surface processing can be achieved even at ‘difficult’ points.

Painting procedure takes place from qualified staff in a paint booth and involves carefully selected stages such as:

PAINTING

During the truck-body manufacturing, apart from the technical specifications, special attention is also given to the anti-rusting protection and painting. The truck-body development takes place on a special-made base and not on the chassis of the truck. In this way the optimum quality of surface processing can be achieved even at ‘difficult’ points.

Painting procedure takes place from qualified staff in a paint booth and involves carefully selected stages such as:

Rust and oil removal from all surfaces by grinding and nitro thinner washing

Application of two component polyester filler and additional grinding in order to achieve smooth surfaces

Anti-rusting protection with two component solvent based epoxy coating

Painting in two layers with two component polyurethane top coat

Visual inspection of final product and paint thickness measurement

QUALITY

Quality control stages of product development include the following checks:

QUALITY

Quality control stages of product development include the following checks:

Dimensional and technical specifications

Bolting and frame support.

Welding

Operation at maximum payload conditions

High pressure circuits

Safety during operation and transportation

Visual and operational inspection of final product

Computational and engineering inspections

Stability of complete vehicle

Surface quality and paint thickness

External laboratory mechanical testing (whenever required)

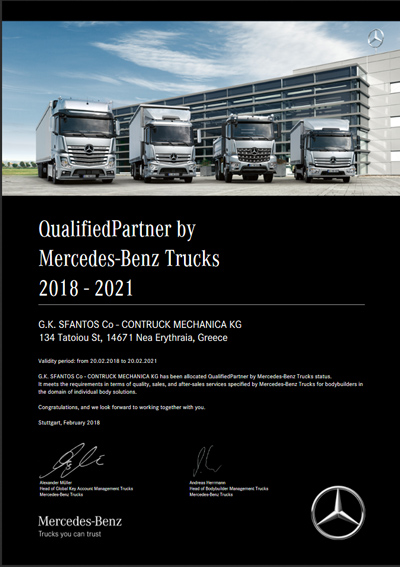

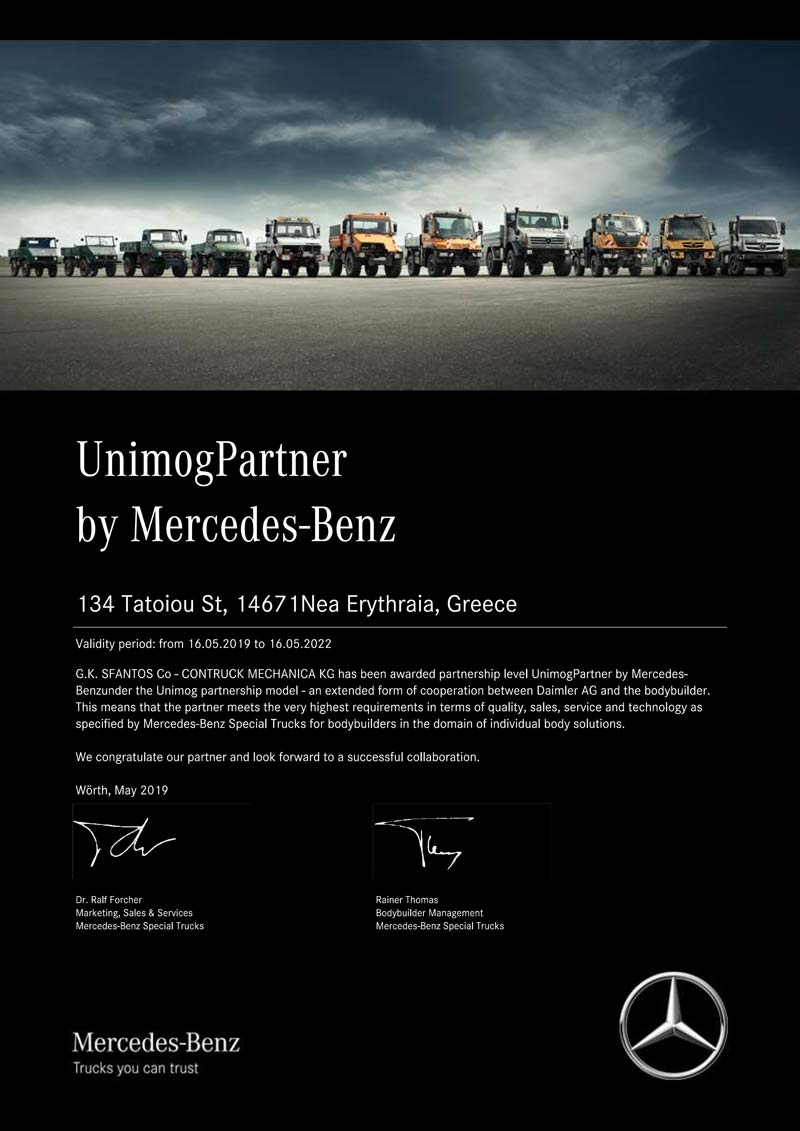

Certificates

The company is fully registered and licensed from the Greek industrial authority for the construction and service of truck–bodies, trailers, semi-trailers and special vehicles and is certified by TUV Austria Hellas for its quality management according to EN ISO 9001:2008.CONTRUCK MECHANICA has been also certified as qualified truck body-builder from MERCEDES – BENZ Hellas and IVECO Spa.

Warranty

CONTRUCK MECHANICA provides at least one year warranty for every product and keeps sufficient stock of engineering components and parts for a minimum period of ten years.

After Sale Support

Special attention is always given to the continuous after sale support and service of our products. Being close to every single customer from the design stage until the final delivery, we have managed to gain high percentage of really satisfied clientele.